Touch Screen Universal Hardness Tester: Multi-Method Precision Testing

Touch Screen Universal Hardness Tester

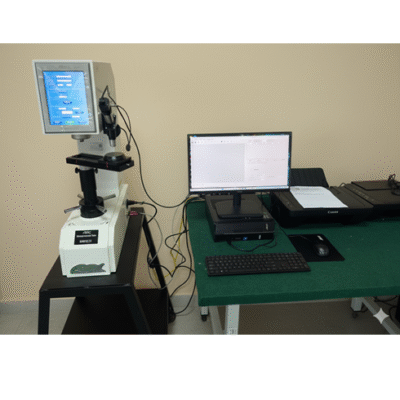

The Touch Screen Digital Universal Hardness Tester is an advanced, fully-integrated hardness testing system that combines Brinell, Rockwell, and Vickers test methods in a single, user-friendly platform. Featuring an intuitive 8-inch touch-screen interface and closed-loop force control technology, this instrument delivers exceptional accuracy and versatility for comprehensive material hardness evaluation across all metals, alloys, and plastics.

Key Features & Benefits

-

Multi-Method Testing Platform: Equipped with Brinell, Rockwell, and Vickers test methods in one integrated system, eliminating the need for multiple dedicated testers and providing unparalleled application flexibility.

-

Advanced Control System: The 8-inch touch-screen interface offers intuitive operation and real-time test monitoring, while the closed-loop load cell system ensures high accuracy without requiring manual weight installation.

-

Automated Force Calibration: Test force automatic correction with automatic compensation for each range significantly improves force accuracy and ensures consistent, reliable results across all test scales.

-

Intelligent Data Management: Features ISO/ASTM automatic hardness conversion, Rockwell curvature radius correction, and USB data export to Excel format, enabling seamless data processing and analysis.

-

Secure Operation: Password protection for setup parameters ensures test integrity and prevents unauthorized changes to critical testing configurations.

-

Modular Maintenance Design: Engineered with modular components for easy service access, reducing downtime and simplifying long-term maintenance.

Specification:

| Model | EI-BRV187.5TS | |

| Scale | Brinell | HBW1/5, HBW2.5/6.25, HBW1/10, HBW2.5/15.625, HBW1/30, HBW2.5/31.25, HBW2.5/62.5, HBW10/100, HBW5/125, HBW2.5/187.5 |

| Rockwell | HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK, HRL, HRM, HRP, HRR, HRS, HRV |

|

| Vickers | HV5, HV10, HV20, HV30, HV40, HV50, HV60, HV80, HV-100, HV120 |

|

| Test force | Brinell | 5kgf (49N), 6.25kgf (61.25N), 10kgf (98N), 15.625kgf (153.125N), 30kgf (294N), 31.25kgf (306.25N), 62.5kgf (612.5N), 100kgf (980N), 125kgf (1225N), 187.5kgf (1837.5N) |

| Rockwell | 60kgf (588N), 100kgf (980N), 150kgf (1471N) Initial test force:10kgf(98N) |

|

| Vickers | 5kgf (49N), 10kgf (98N), 20kgf (196N), 30kgf (294N), 40kgf (392N), 50kgf (490N), 60kgf (588N), 80kgf (784N), 100kgf (980N), 120kgf (1176N) |

|

| Indication Accuracy | Brinell 8 ~ 650HB (δ/%): ±2.5 Rockwell ±0.1HR Vickers ±2 |

|

| Repeatability | Brinell 8 ~ 650HB (Hcf/%): ≤3.0 Rockwell 0.5HR Vickers ≤2.5 |

|

| Hardness Range | Brinell 8 ~ 650HBW Rockwell 20 ~ 100HR Vickers 8 ~ 2900HV |

|

| Force Error | ˂0.5% | |

| Holding Time | 0 ~ 60s | |

| Minimum Measuring Unit | 0.1μm | |

| Allowed Maximum Sample Size (Test Space) | Allowed Maximum Sample Height in Vertical

220mm (for Rockwell) 150mm (for Vickers & Brinell test mode) Allowed Maximum Sample Height in Horizontal 200mm |

|

| Magnification Eyepiece | 15x, 2.5x (for Brinell), 5x (for Vickers) (10x, 20x for optional)Total Magnification: 37.5x, 75x |

|

| Implementation of the standards | ISO 6508, ASTM E-18, JIS Z2245 ISO 6506, ASTM E10-12, JIS Z2243 ISO 6507, ASTM E92, JIS Z2244 |

|

| Dimensions | 560 x 350 x 800mm | |

| Weight | Approx. 70kg | |

| Accessories | Operation Software for Brinell / Rockwell / Vickers, Camera and computer set |

|

PDF Data Sheet – Touch Screen Universal Hardness Tester