The Hand Sheet Former is an experimental equipment that using a Rapid-Köthen method for the preparation of laboratory sheets of pulp for the purpose of carrying out subsequent physical tests on these sheets in order to assess the relevant properties of the pulp itself. This process is critical for evaluating fundamental pulp properties like tensile strength, brightness, porosity, and fiber composition without the cost and time of running a full production machine.

The Hand Sheet Former consisted with stainless steel body, a former column, the dryer and front control system are mounted. De-watering suction system, water circulation system, the return water filter and the water container are installed.

Features:

- Stainless steelbody finishing

- Water pump switch – Using tankwater to pump into the cylinder while producing hand sheets.

- PneumaticAgitation switch – Homogenate stirred with pressured air.

- SiphonSwitch – Ready to drain cylinder to form hand sheet.

Applicable Standard:

GB/T24324-2009, QB/T3703-1999, DIN EN ISO 5269-2 & ISO 5269-3, NBR 14380-99, TAPPI T-205, DIN 54358, Zellcheming Merkblatt V/8/76

Specification

| Model | EI-CP01-1D |

| Test Sheet | Ø200mm |

| Vessel Capacity | 11L |

| Vacuum | -0.092 ~ -0.098MPa |

| Vacuum Compress | 0.1MPa |

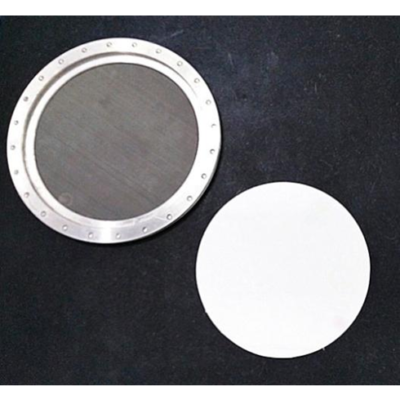

| Mesh Filtration | 60 and 80 |

| De-Watering System | High pressure vacuum suction system |

| Sheet Dryer | Timer 1 to 99 minutes

Temperature up to 120°C Drying Rate 0.7/4h/cm² |

| Agitation | Air Agitation |

| Water Circulation | Auto and Manual |

| Material | Body – Stainless Steel

Mesh Frame – Stainless Steel Former – Stainless Steel Vacuum Pipe – Teflon Dryer – Composites Metal Water Tank – Stainless Steel Seal – Silicon |

| Rate Voltage | 240V, 50Hz |

| Rate Power | 3000W |

| Dimension | 1000 x 700 x 1300mm |

| Weight | Approx. 120kg |

| Standard Accessories | Grid Plate: 60 & 80 with Spare Wire Mesh

Couch Roller x 1 |

PDF Data Sheet – Hand Sheet Former